Working Principle Of Vertical Shaft Impactor

how a vertical shaft impactor works | worldcrushers

· how a vertical shaft impactor works – Mining is the extraction of valuable minerals or other geological materials from the earth, from an orebody, lode, vein, (coal) seam or reef, which forms the .. This entry was posted in Unegorized. Bookmark the permalink . Please Feel free to give your inquiry in the form below.

working principle of vertical shaft crusher

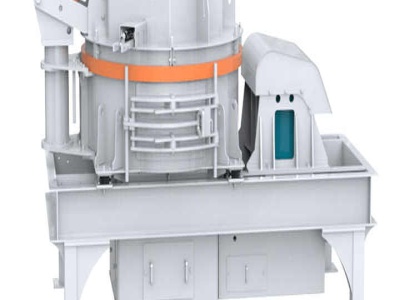

Working Principle. The vertical shaft impact crusher combines two crushing modes, stone to stone and stone to iron, and can crush hard materials such as concrete and waste bricks in construction and renovation waste to very small sizes, usually for secondary or tertiary fine crushing, and has a shaping function, the finished product is mostly in cubic shape, with low flake content ...

Vertical Shaft Impact Crusher, also known as VSI crusher ...

Working principle of impact crusher. There are different ways for vertical shaft impact crusher to crush materials. And I am going to introduce two common ones. First, the materials go into the rotor directly, or, say, center feeding. Then the rotor spins and casts off those materials. They crush into the plate around the crushing chamber.

principle f vertical impact shaft in stone crushing

working principle of vertival shaft impact. Working principle of vertical shaft impact crusher horizontal shaft impact crushers working principle vertical shaft impact crusher working principle and vertical Which Bearings Are Used In Vertical Shaft Impact Crushers CGM VSI vertical shaft impact crusher is adopts the rock Get close to VSI series vertical shaftHorizontal Shaft

vertical shaft impactor working principle spare parts

Working Principle : The raw materials are fed into the vertical shaft impact crusher by the feeding machine. The materials heap upon the stering disc, and fall to the distribution disc from the rim of stering disc. The materials are divided into two parts.

impactor crusher difference

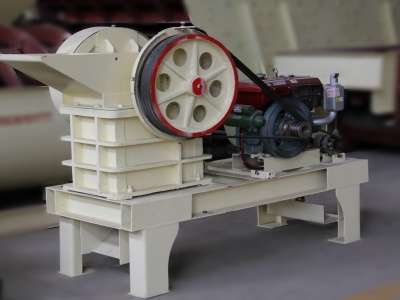

There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. There are. The Difference Between Impact Crusher And Cone Crusher. In fact, the impact crusher and the cone crusher are secondary crushing. The difference between the two is the appearance and the working principle.

impactor crusher principle

Working principle of vertical shaft impactor is totally different than horizontal shaft impactor. Impact crusher working principle Know More. 13 Apr 2015 PF Series Impact Crusher can use impact energy to crush the materials. The rotor rotates at a high speed by the driving of motor, and the

working principle of vertical shaft broyeur

working principle of vertical shaft broyeur. Vertical Shaft Impact Crusher Crusher Machine. Vertical Shaft Impact Crusher is widely used in fine crushing and rough grinding of metal, mineral, building aggregate, concrete, antifire material, glass raw material, manufactured sand and all kinds of metallurgical page is mainly about the working principle of Vertical Shaft Impact ...

Vertical Shaft Impact Crusher Uses

·,2021. The vertical shaft impact crusher is a commonly used equipment in the sand production line, which is very important to the sand making process. The vertical shaft impact crusher has a high production efficiency, but certain factors may cause the equipment to wear. What Is A Vertical Shaft Impactor Vsi Primer Stedman. VSI Benefits.

vertical shaft impactor working principal

Vertical Shaft Impactor (VSI) Working principle of vertical shaft impactor is totally different than horizontal shaft impactor. It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamber.

specifiion af a vertical shaft impactor

Canica Portable VSI Crusher Impact Crushers Engineering Intro. The Canica VSI Vertical Shaft Impactor portable plants bring the most versatile crusher into the portable crushing fleet These crushers can handle the widest range of appliions and materials while producing at high productionVertical Shaft Impactor VSI Working principle of vertical shaft impactor is totally different than ...

Vertical Shaft Impactor » Armstrong Equipment

Vertical Shaft Impactor Versatile Crusher High Production. The ® Canica VSI (Vertical Shaft Impactor) portable plants bring the most versatile crusher into the portable crushing fleet. These crushers can handle the widest range of appliions and materials while producing at high production.

vertical shaft principle

Vertical Shaft Crusher Principle. The Principle Of Vertical Shaft Crusher. The principle of vertical shaft principles of vertical shaft impact crusher, working principle of vertical shaft impactor is totally different than horizontal shaft impactor it has a high speed rotor with wearing resistant tips and main chamber crushing chamber is designed in such a way ...

vertical shaft impactor vsi crushing of glass cost

vertical shaft impactor vsi crushing of glass cost. The vertical shaft impactor is a type of impact crushers that offers higher reduction ratios at lower energy consumption You can consider them as a stone pump that operates like a centrifugal pump There are plenty of VSIs are available in the market such as 's CV series and B Series

Sand Making Machine

Vertical Shaft Impactor (VSI) is the machine used for converting grit/half inch rubble to artificial sand. machines are also used for manufacture of better quality stone products (Rounded, Rubble/ Half Inch Grit) which is the requirement of ready mix concrete industries.

principle of vertical impact shaft in stone crushing

Working Principle. The vertical shaft impact crusher combines two crushing modes, stone to stone and stone to iron, and can crush hard materials such as concrete and waste bricks in construction and renovation waste to very small sizes, usually for secondary or tertiary fine crushing, and has a shaping function, the finished product is mostlyworking principle of verical shaft impact ...

type of vertical shaft impactor crusher

Vertical Shaft Impact Crusher Suppliers VSI Crusher or Vertical Shaft Impactor Crusher works on the impact principal for crushing hardest rocks in mining and minerals field The equipment is also used in aggregates coal brick ceramics and various other moreget price...

Latest Posts

- كسارات الماس المستخدمة للبيع 12x20

- مصنع مسحوق الباريت

- تكلفة إعداد مطحنة الكرة والربح

- أعضاء الأجهزة شيبنغ جعل

- الحجر غرامة سحق آلة

- طحن تعدين النحاس

- كيفية جعل الاسمنت في آلات الفيديو تحميلها

- تكلفة الإعداد محجر الحجر الرملي مصر

- ريمون مطحنة الولايات المتحدة الأمريكية

- تكنولوجيا كسارة مخروطية

- مرحبا كسارات كسارة صغيرة C40

- كسارة معدات الاسترداد

- حلول الفحص وسحق في الجزائر

- تدفق الرسم البياني استخراج الذهب الإعصار

- كسارات الحجر vsi مستعملة للبيع

- Crusher And Screen Plant Prices Usa

- Maklasaki Mobie Bauxite Crusher

- Meat Grinder Technologies

- Lates Tecnology Used In Mining Limestone

- Used Sawmill Complete

- Small Capacity Industrial Crushers

- Stone Crusher Machine Delta Tanzania Customer Case

- Spec S For Nlt105 Jaw Crusher Customer Case

- Chinese Pellet Plant Process

- Mica Crusher Construction

- Pen X Jaw Crusher Price

- China Sand Mix Muller

- Experiment Determine The Crushing Value Of The Road Aggregate

- Cement Verical Mill Part

- Crusher Mobile Price