Primary Saheite Crusher Grizzly

Vibrating grizzly feeder/scalper

Features Vibrating grizzly feeder/scalper. Roc Impact (ROC) vibrating grizzly feeders are designed mainly for fixed primary crushing plants. They regulate the feed rate to the crusher while separating materials by size. The vibration unit is run by two vibrators loed underneath, or with a motordriven eccentric driveshaft.

Construction, Working and Maintenance of Crushers for ...

Material which is too large to pass through a specific size of a screen or grizzly opening. Primary Crusher The first crusher in a crushing system into which material is fed. Succeeding crushers in the system are referred to as secondary (second), tertiary (third) or quaternary (fourth) crushers.

thyssenkrupp launches nextgen ERC primary crusher

· The crushing plant used for the tests consisted of a feed hopper, a vibrating feeder, the crusher with integrated primary scalping grizzly, a discharge belt conveyor, steel structure and a power unit. The most important process and machine parameters were determined in a test operation lasting more than six months.

Screens

Grizzly screens SGH GRIZZLY SCREEN The SGH circular motion screens are recommended for installation between a primary feeder and a primary crusher. Typical feed material is blasted rock, ripped rock or gravel with high fines content, often containing difficult wet natural fines or clay. These screens have a single grizzly or plate type of ...

RAMAKRISHNA CRUSHER INDUSTRIES

Primary Jaw Crusher Secondary Jaw Crusher Cone Crusher Double Toggle Jaw Crusher Vibrating Screen Vertical Shaft Impactor (Vsi) Horizontal Shaft Impactor (Hsi) Grizzly Feeder Vibro Feeder Sand Washer (Bucket Type) Hydrocyclone Washer Belt Conveyors

grizzly feeder in crusher

Grizzly bars and feeders improve primary crushing efficiency Vibrating Grizzly Feeder A vibrating grizzly feeder (VGF) is loed at the bottom of the hopper and directly feeds into the jaw crusher. As its name would suggest, the VGF vibrates and this agitation causes the material to separate.

Grizzly feeder

Description. VG Series™ scalping screens, or grizzly scalpers as they are also called, are utilized in the primary crushing stage. They scalp the primary feed allowing fines to bypass the primary crusher. Screening the fines before the crusher results in higher overall capacity of the primary crushing .

Jaw Crushers

Maximum Crushing Power. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaws; one is fixed while the other reciproes. There are also primary and secondary types of these crushers.

Abhishek Enterprises | ABHISHEK ENTERPRISES is in the ...

Abhishek Enterprises ABHISHEK ENTERPRISES is in the services of people around the country, manufacturing high quality stone crushing plants and equipment and its spares to the entire satisfaction of its clients. AE Manufactures Jaw Crusher (Primary Crusher), Granulator (secondary crusher), Smooth Roll crusher, Vibrating Screens, Vibrating Grizzly, Vibro Feeders and Belt Conveyors in .

Gyratory Crusher Explained

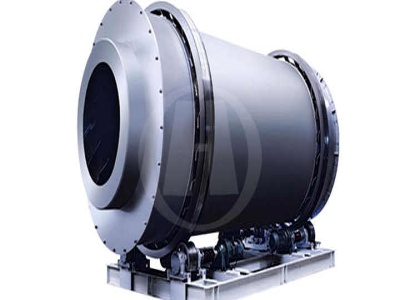

Gyratory Crusher Components . Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a 'Gate's crushers' in the early years). A primary crusher is designed to receive runonmine (ROM) rocks directly from the mines.

Grizzly Feeder

Primary Mobile Crusher; Secondary Mobile Crusher; Spares; Careers; Contact Us; Download; Search; Menu Menu; Grizzly Feeder. Grizzly Feeder. SALIENT FEATURES. Huck Bolted construction; Ultra Durable; Low Power consumption; Scalping Deck; With Unbalanced Motor; For details please refer the brochure. View Brochure. GRIZZLY FEEDERS. Model Size (mm ...

Wheeled Jaw Crusher | MPS

MPS Wheeled Jaw Plants combine the rugged reliability of the our jaw crushers with the high stroke vibrating grizzly feeders for a high production portable primary crushing machine. These plants are the lead machine in many different crushing spreads and will handle most any material. Whether shot rock, sand and gravel, or recycle ...

Major Mines Projects | Mutanda Mine

The ROM ore will be tipped into a ROM tip bin equipped with a static grizzly which will ensure that oversize material will not report to the primary crusher (oversize material can choke the crusher). Ore will be withdrawn from the ROM tip bin using a variable speed apron feeder to a vibrating grizzly feeder (to scalp off fines) ahead of the primary crusher.

GRIZZLY SCREENS

Grizzly Screens are very strong and robust screens suitable for the toughest high capacity appliions. These screens have at least two grizzly sections, which allow them to operate under tough conditions as primary scalping or secondary prescreening. There are two types of grizzly screens;

BTI Rockbreaker Systems

BTI offers a full line of rockbreaker systems suited for the softmedium rock crushing appliions. These systems feature a wide range of working lengths allowing the rockbreaker to rake and break materials while maintaining a constant flow of production through the crusher.

Impact Crusher | Trakpactor 260 | Powerscreen

Impact Crusher. The Powerscreen® Trakpactor 260 is a compact impact crusher which has been designed to offer both excellent reduction and high consistency of product yield. With its compact design and ease of mobility, the Trakpactor 260 is primarily suited to recycling, demolition and mining appliions. Capable of processing a wide range of ...

PAN FEEDERS AND GRIZZLY SCREENS

They are set of two machines placed under the primary hoppers; a pan feeder and a grizzly screen to separate fine material efficiently before entering the primary crusher. They feed raw materials to the primary crushers without fines in it. MTM Pan Feeders and Grizzly Screens with their robust

BTI Rockbreaker Systems

BTI offers a full line of rockbreaker systems suited for the softmedium rock crushing appliions. These systems feature a wide range of working lengths allowing the rockbreaker to rake and break materials while maintaining a constant flow of production through the crusher. Available in three models. Medium (2000 ftlb breaker with a 16 ...

SR ROLLER GRIZZLY, ROLLER SCREEN, ROLLER SCREEN ...

ROLLER GRIZZLY The Roller Grizzly is designed for scalping and screening duties of low abrasive materials ( limestone and coal). Harder and abrasive materials are not suitable for the Roller Grizzly ( abrasion index (Ai) higher than 0,03). This screen model is considerably compact compared to the conventional screens and its ability

XA400S XR400S

With an aggressive crushing action and a high output even at tight settings, the Metrotrak is ideally suited for small to medium sized operators in the mining, quarrying and recycling industries. The Powerscreen® X400S range of high performance primary jaw crushing plants are designed for medium scale operators in quarrying, demolition, recycling and mining appliions.

Latest Posts

- نوع الكسارة في قائمة مصر

- مزايا آلة كسارة الحجر

- منجم الذهب سحق تكلفة

- ذروة معدات الضغط العالي

- موردي معدات المطحنة كسارة مصر

- يستخدم آلة سحق ملموسة

- أحجار الدورة للطحن

- الشركات مسحوق الحجر الجيري المورد في المملكة

- المصنعة محطة كسارة المملكة العربية السعودية

- ساياجي خام الحديد كسارة الحجر

- محطات استخلاص الرماد المتطاير

- سعر كسارة مطحنة ريمون كسارة

- الشركة المصنعة للناقل في الصين

- السعودية آلة طحن الصين

- التعدين stonewall مصر

- Safe Operating Procedure Fr Cement Mill

- Carbon Stripping Gold Equipment

- Iron Making Process In Blast Furnace

- Mobile Coal Crushing Plant Features Crusher For Sale

- Wood Mill Takoma Wa

- Estimated Cost For Sand Cleaner Device Cost

- Amelia Vid By Millz 18 Min

- Second Hand Tissue Paper Mills

- Magnesite Ore Vsi Crusher Manufacturer

- Crusher With Ce Iso Certifie

- Used Gwp Plant For Sale

- Cadmium Mining Cadmium

- Vertically Integrated Textile Mill Definition

- Saiji Crusher Meshines

- Rough Rock European Version Of Sand Machine