What Is The Working Principle Of Ball Mill Pdf

Principle Of The Ball Mill Ball Mill 2fishygir

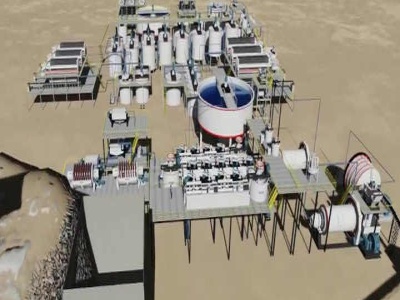

Ball Mill Working Principle. Ball mill is one of the high fine grinding machine is widely used in industrial production, there are a lot of its type. It is widely used in mineral processing, building materials and chemical industry etc. But do you know how does it work this paper will mainly explain the working principle of ball mill for you.

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

on wear is another issue. Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later. K. H. Schröder July 2003 K. H. Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDER_ROLLS_

Working Principle Of Vertical Ball Mill

Principle Of Ball Mill Pdf Ceo Socialmedia. The working principle of ball mill meetyou 22, 2019 the ball mill consists of a metal cylinder and a working principle is that when the cylinder is rotated, the grinding body ball and the object to be polished material installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

ball mill principle construction working pdf

ball mill principle construction working pdf. If you want to learn about our products, please call or write mail consultation. D sumanth kumar, hM mahesh, in synthesis of inorganic nanomaterials, ball milling a ball mill is a type of grinder used to grind and blend bulk material into qdsnanosize using different sized ballsThe working principle is simple impact and attrition size reduction ...

Ball Mill Principle Operation Theory Pdf

Ball Mill Principle Operation Theory Pdf. Ball mills theory ball mill principle operation theory pdf sbm ball mills theories and principles pdf cachedball mills are used primary for single stage fine grinding regrinding and as the second stage in two stage grinding circuits. More Details

Ball Mills

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral ...

Introduction to Milling Tools and Their Appliion

Ball end mills produce a radius at the bottom of pockets and slots. Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing appliions. Flutes Spiralshaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill is down in a slot or a pocket. The most common options are 2, 3, or 4 flutes. The more flutes ...

High energy ball milling process for nanomaterial synthesis

It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960. It was found that this method, termed mechanical alloying, could successfully produce fine, uniform dispersions of oxide particles (Al

Ball Mill Working Principle

Ball mill is one of the high fine grinding machine is widely used in industrial production, there are a lot of its type. It is widely used in mineral processing, building materials and chemical industry etc. But do you know how does it work? this paper will mainly explain the working principle of ball mill for you. Ball mill is composed of horizontal cylinder, access to materials and a a ...

Powder metallurgy – basics appliions

Rod mills: Horizontal rods are used instead of balls to grind. Granularity of the discharge material is 4010 mm. The mill speed varies from 12 to 30 rpm. Planetary mill: High energy mill widely used for producing metal, alloy, and composite powders. Fluid energy grinding or Jet milling: The basic principle of fluid energy mill is to induce

Principle Of Ball Mill In Pdf

Principle Of Ball Mill In Pdf. Grinding in Ball Mills Modeling and Process Control Vladimir Monov, Blagoy Sokolov, Stefan Stoenchev The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material feeders, and the system for principle in the development of each model is to establish mass balance or energy

Ball Mill

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones. The ...

SAFETY RULES BASICS FOR MILLING MACHINES

FIRST Robotics Team 4153 Milling Machine Qualifiion Test 1. The first item of procedure to operate the milling machine is A. secure work piece. B. set cutting speed. C. turn on power. D. obtain teacher permission. 3. Make measurements or setups only when A. you have permission. B. you have read and understand safety rules.

Ball Mill Working Principle Pdf

Ball Mill Working Principle Raw Material Pdf Working principle ball mill production line is mainly consisted of ball mill hopper feeder conveyor bucket elevator powder classier when it works materials are evenly fed into the ball mill by the feeder at the bottom of the raw material storage after being grinded they outow from the outlet and are transported to the powder.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills have been used for more than one hundred years, the design is still being improved in order to reduce the grinding costs. HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants. The paper describes the approach for ...

Page 1 Ball Milling Theory

Ball Milling Theory Introduction: Figure 1: Ball milling terminology. I was first given the formula for gunpowder by my Uncle at age 14, after he had observed my apparent obsession with class C fireworks. Being a scientist who had experimented with the ancient recipe himself during his youth, he thought I should try making my own fireworks. When I found out that these three simple ingredients ...

ball mill working principle pdf

021 243 21 42. ball mill working principle pdf. Home All Posts Unegorized ball mill working principle pdf

Impact Load Behavior between Different Charge and Lifter ...

A ball mill (Figure1) is the key piece of equipment for secondary grinding after crushing and is suitable for grinding all types of ores and other materials. Ball mill are used in the mining, cement, chemical and agricultural industries, particularly tumbling ball mills [1–4]. The comminution process is dependent on the rotation of the mill to lift the grinding media for reducing particle ...

Work Of Ball Mill Pdf

Ball mill working principle and main parts. ball mill working principle to be chosen according to the grinding material material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body when the ball mill cylinder rotation time grinding body due to inertia.

(PDF) Grinding in Ball Mills: Modeling and Process Control

· The balls mills were then compared based on several indiors of energy efficiency, productivity and processing speed. The results show that the energy input is better utilized in mills that work ...

Introduction to Machining: Milling Machine

work. Ball end mills can produce a fillet. Formed milling cutters can be used to produce a variety of features including round edges. •Use More flutes for finer finish at lower MRR. Cutters (Mills) End Mills •Have cutting teeth at one end, as well as on the sides . Installing Removing Cutters •End mill cutters can be held by the spindle in several ways; a few of the ways are shown in ...

Rolling Process: Working, Appliion, Defects, Type of ...

Rolling Process: Definition, Working, Appliion, Defects, Type of Rolling Mills [PDF] Written by Saswata Baksi in Manufacturing Process. Rolling is the deformation process of a metal that is widely used in the metal forming process. It is done by passing the strip of the metal between the rollers. This paper discussion will be made about the ...

Latest Posts

- المستخدمة مخروط محطم بيع

- آلة كسارة الكاولين معدات التعدين

- تأثير سحق إيه الخرسانة

- مواصفات الكسارات مخروط العالي

- شراء الحصى محطم في الفلبين

- افضل كسارة حجارة في الاردن

- كسارة صخور صغيرة للبيع كريغزلست

- كسارة للبيع تفاصيل

- يعالج مصنعو الكسارات الحجرية الجزائر

- مصنع لتجهيز خام المنغنيز في الجزائر

- مصنع لتجهيز خام النيكل للبيع

- مطحنة loesche الأسطوانة العمودية

- آلة طحن الركيزة pg14 مصر

- السعري حجر محطم 50 طن مربى

- اجتماع كسارة الصخور

- Vertical Mill Of Cement Plant

- Craigs List Soft Rock Crusher

- Line For Grinding Ball Mill

- Iron Ore Grinding Mill Manufactures Supplier

- Produsen Mesin Gerinda Rotary Di Canada

- High Quality Dry Or Wet Ball Mill Manufactures In China

- Grinding Mill For Home

- Belt Conveyor In Cear谩

- Cost Of Knelson Gold Concentrators

- Limestone Crushing Plant In Paraguay

- Quarry Business Customizable

- Rapids 8800 Rock Crusher

- Stone Jaw Crusher Manufacturers Crushers Machinery

- Air Sweft Coal Mill Working Principle

- Agen Belt Conveyor Continental Jakarta