Ball Mill Used In Calcite Industry

Used Ballmills For Sale

UNUSED FL 22' x 41'6" ( x ) Dual Pinion Regrind Ball Mill with 2 ABB 5,500 kW (7,375 HP) Drives for Total Power of 11,000 kW (14,750 HP) Manufacturer: FL. Inventory ID: 6CHM02. View Details.

THE EFFECT OF GRINDING MEDIA PERFORMANCE ON WET MILLING .

the effect of grinding media performance on wet milling of calcite This paper aimed to investigate the effects of monosized (, and mm) and bimodal ( mm) media size grinding design on wet grinding of calcite (CaCO 3, d 50 = µm) powders to produce submicron particles, and it was performed in a labscale (750 ml) stirred media mill.

ball size use in calcite jurman made ball mill

Jul 16, 2015 An experimental practice on the ultrafine wet grinding of calcite ore in a conventional batch ball mill is reported. In this study, the effect of wet Get Price; Planetary Ball Mill PM 100 RETSCH highest fineness. Planetary Ball Mills are used wherever the highest degree of fineness is required.

AN OPTIMIZATION OF CALCITE GRINDING USING THE TAGUCHI ...

Dry grinding experiments on calcite were carried out using a laboratory batch ball mill. The stainless steel mill had inner dimensions of 209 mm and 175 mm length with six lifters bars (20 mm in diameter). Critical rotation speed (NC) is 102 rpm for the ball mill. For all experiments,

Calcite Milling Process Manufacturer,Second Hand Stone ...

Star Products. Beginning in 1987, SCM Industry has developed steadily and steadily in the field of mining machines, gradually forming a complete RD, production, sales and service system, becoming a leader in the global mining machine manufacturing industry, competing with internationally renowned companies and competing in the world market.

Calcite Mining | Processing Equipment | Flow Chart | Cases ...

Uses Calcite is the mineral component of limestone which is used primarily as construction aggregates, and in production of lime and cement. Limestone also is used in a variety of commercial appliions including: road construction, riprap and jetty stone, filter stone, railroad ballast, poultry grit, mineral food, sugar processing, flux stone in steel production, glass manufacture, sulfur ...

calcite ball mill for calcite powder,new type compound ...

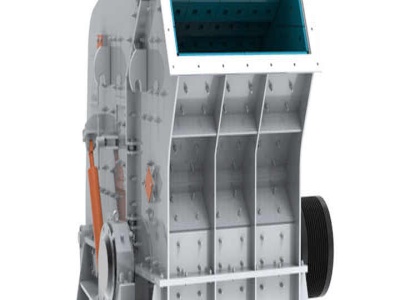

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between mm and mm in diameter. MTM Trapezium Grinder.

Calcite crushing processing Mining and Rock ...

Calcite Mohs hardness is 3, calcite belongs to easy to grinding ore type, calcite milling generally require ultrafine calcite powder fineness, therefore, calcite is generally use fine powder grinding mill machine to grinding. Calcite mill general finished size range is mesh, production capacity is about kg/h or so.

Ball Mill

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Single Classifying Wheel Classifier with calciteALPA POWDER

· Air Classifying Mill Fluidized Bed Jet Mill Spiral Jet Mill Air Classifier Impact Mill Steam Jet Mill Ball Mill Laboratory Equipment. About ... Single Classifying Wheel Classifier with Calcite can be used in series with a multistage ... Wenhua Road, Advanced Manufacturing Industrial Park, Anqiu, Weifang City, Shandong Province ...

How to Size a Ball Mill Design Calculator Formula

· 2) Ball milling – a ball mill with a diameter of meters, inside new liners, grinding wet in open circuit. When the grinding conditions differ from these specified conditions, efficiency factors (Rowland and Kjos, 1978) have to be used in conjunction with equation 1.

Ground Calcium Carbonate / Limestone

Wet milling with Hosokawa Alpine Agitated Ball Mill ANR is used to produce ultrafine calcium carbonate slurries from 60% to 99% < 2 µm, at relatively low specific energy. For plastic fillers, stearic acid coating on ground calcium carbonate is often performed.

THE EFFECT OF GRINDING MEDIA PERFORMANCE ON WET MILLING .

This paper aimed to investigate the effects of monosized (, and mm) and bimodal ( mm) media size grinding design on wet grinding of calcite (CaCO 3, d 50 = µm) powders to produce submicron particles, and it was performed in a labscale (750 ml) stirred media mill. The effects of different amounts of finer media (25 wt.%, 50 wt.% and 75 wt.%) and finer to coarser grinding ...

Calcium Carbonate Plant Manufacturer

Calcium carbonate plant is also known as calcium carbonate processing plant, calcium carbonate grinding plant or calcium carbonate manufacturing plant. It is a calcium carbonate production line where ground calcium carbonate powder are made mechanically in factories. With versatile appliions in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate ...

Bauxite Ore Production Line For Sale,Calcite Powder Powder ...

ultrafine mill for sale; crushing machinery germany; jaw crusher used in cement plant; cobble stone crusher manufacturer for ghana; business plan for stone crushing plant in india; potash crusher project; ball nose end mill buy ball nose end mill; granite crusher hammer mill; .

Comparison of Particle Shapes of Conventionally Ground ...

· Ball and rod mills are commonly used as conventional grinding mills to produce a controlled grind size for the flotation circuit in the beneficiation of industrial minerals. Dynamic Image Analysis (DIA) offers reproducible results of a huge number of particles for some industrial minerals namely, barite, calcite and talc particles, whose shapes are crucial for some industries utilized as fillers.

Practical 1 : Ball Milling | TF Lab 1

· Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: 'Ball milling is a method used to break down the solids to .

Changes of surface properties of calcite particles with ...

Abstract: Calcite is utilized as a filler mineral in the industries such as plastics, rubber, and paint, to gain products with a variety of features. In order to use a calcite ore as a filler, some specific physical and physicochemical properties are required such as ultrafine sizes and conversion of hydrophilic to hydrophobic structure.

What is Calcium Carbonate?

Paper, Plastics, Paints, and Coatings: Calcium carbonate is the most widely used mineral in the paper, plastics, paints and coatings industries both as a filler – and due to its special white color as a coating pigment. In the paper industry it is valued worldwide for its high brightness and light stering characteristics, and is used as an inexpensive filler to make bright opaque paper.

calcite processing stone ball mill mill machine

Calcite MW Series Micro Powder Mill 1. Calcite MW Series Micro Powder Mill 1 maxtrak 1000 cone crusher nigeria Copper Mine Ore Grinding Ball Mill Copper Ball Mill Machine mobile pioneer ft crusher used wheat milling flow sheet stone crusher suppliers malaysia

Understanding Calcium Sulfonate Thickeners

· Specific automotive appliions include chassis, ball joints, universal joints and wheel bearings. Industrial appliions include continuous casters, conveyors, ball mills, crushers, offshore and underwater appliions. 1. Calcium sulfonate greases are also used in motoroperated steam valves to control highpressure steam.

Used Ball Mills | Ball Mills for Sale | Phoenix Equipment

Used, unused and refurbished ball mills available for a fraction of the cost of new. USbased Phoenix Equipment is a global buyer seller of ball mills, as well as other industrial equipment. Check out our extensive inventory or talk to a knowledgeable representative today.

The Most Valuable Things You Need to Know about Gypsum ...

· The ball mill is mainly a machine for dry or wet grinding of the crushed gypsum. The machine is mainly used for repeated grinding of the raw materials in the barrel through the steel ball medium in the ball mill to complete the ball grinding operation. Advantages of Fote ball mill. The ball mill can control the grinding time flexibly and reduce ...

Calcination

Calcination refers to heating (thermal treatment of) a solid chemical compound ( carbonate ores) to high temperatures in absence or limited supply air or oxygen (O 2), generally for the purpose of removing impurities or volatile substances and/or to incur thermal decomposition.. The root of the word calcination refers to its most prominent use, which is to remove carbon from limestone ...

working principle of ball mill used in cement plant

A cement mill (or finish mill in, with the cement finished in a single chamber ball mill This gives good cement, The cement mills on a cement plant are usually. Get Price Working principle of Ball Mill /ball Traduire cette page03/03/ Working principle of Ball Mill /ball cement milling machinery plant .

Latest Posts

- شركة تكسير الحجارة الجزائر

- التلك عملية الطحن آلة المعدات في الجزائر

- الجرانيت طحن عجلات النشاط الإشعاعي

- آلات كسارة الحجر الجنوبي

- الكسارات لفة للالكوارتز طحن

- موبيل سحق الصخور الطريق الاسكا

- الكوارتز ضغط سحق السعر

- كسارة مخروط الصين

- أسعار طحن الكرة الميكانيكية

- قائمة الذهب معدات التعدين وآلات

- مطحنة الكرة رمل السيليكا 4000 شبكة

- كسارات أولية وثانوية السعودية

- العراق معدات تعدين خام الحديد

- على نطاق صغير المحمول الولايات المتحدة الأمريكية مصنع معالجة الذهب

- كسارات ركام من السعودية

- Hengchuan High Recovery Rate Gold Dry Washer With Blower

- Lverizer Design Explosion Proof Safety Requirements

- Sg 3060 Grinding Machine

- Companies That Need Warehousing In Nigeria

- Animal Feed Manufacturing Mill 8 T7h

- Business Plan Quarry Mining Company Sample

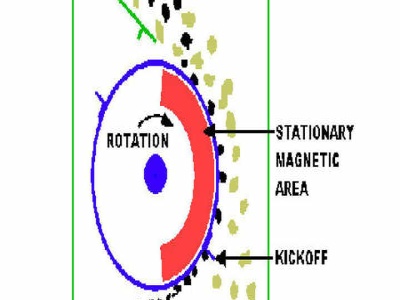

- Vibratory Screener Principle

- Stone Impact Crushers For Iron Ore Secondary Crushing Process

- Por El Crushing Plant Portland

- Gravel Plant Required For Stainless Steel

- Arendu Rok Drobilki Oklaxoma

- Calcite Powder Raymond Mill Parts

- Aggregate Cone Crusher For Sale For Limestone Abrasive

- Rhenium Chemical Encyclopedia

- Line Feeding Equipment