Ball Mill Thermal Power Plant

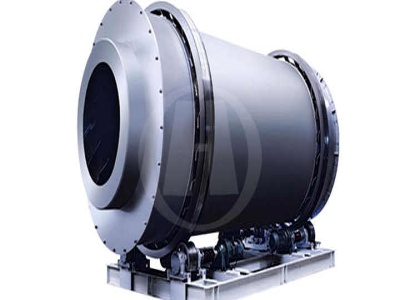

Ball Mill In Thermal Power Stations

Ball Mill In Thermal Power Plant t Ball Mill In Thermal Power Plant. Ball mills may not be the most efficient means of size reduction but their reputation for product consistency and their simplicity of operation have made them an historic plant favoriteince the 1980s, Cement plants are increasingly looking to vertical roller mill More Details. ball mill thermal power plant in ...

Ball Mill Used in Minerals Processing Plant | Prominer ...

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to .

Ball Mills In Thermal Power Plant

Ball Mill In Thermal Power Plant Ecopub. However, this method is not suitable for power plant having ball and tube type of mills due to higher risk of fire hazard. Approximately, to lakh tonnes of Biomass pellets are required for 7% blending in a thermal power plant of 1000MW capacity. 4. Ball Mills In Thermal Power Plants Paraguay . Coal mill in power plant manufacturing companies ...

Water for thermal power plants: Understanding a piece of ...

· Thermal power plants generate around 80 per cent of the electricity produced in the world 3, by converting heat into power in the form of electricity. Most of them heat water to transform it into steam, which spins the turbines that produce electricity. After passing through the turbine, the steam is cooled down and condensed to start the cycle ...

Renewable Energy

FTJ Power Plant started its operations in September 2016, and supplies electricity to National Grid as FeedIn Tariff Project with a total capacity of MW. The plant uses EFB to generate steam and electricity which are supplied to its two major power consumers in Sahabat Oil Products and Sahabat Kernel Crushing Plant. Besides these, the electricity is also supplied for nonmanufacturing ...

Flue Gas Desulfurization (FGD) Working | Thermal Power Plant

The reagent preparation system of flue gas desulfurization (FGD) includes a Wet ball mill and cyclone classifiers which produce a finely ground limestone slurry at 90% solids passing through 325 mesh. One mill slurry tank and one slurry pump is supplied for one wet ball mill. The mill slurry pump will send limestone to ball mill classifier to classify big size limestone. Then, the overflow of ...

Thermal Power Plant Components Working Principles ...

Thermal Power Plant Explanation. Thermal Power Plants also called Thermal Power Generation Plant or Thermal Power Station. A thermal power Plant / Station is used to convert heat energy to electric power / Energy for and commercial the process of electric power generation, steamoperated turbines convert heat in to mechanical power and then finally electric .

Preparation and Characterization of Nano structured ...

· The following milling conditions were maintained: loading of the ball mill with 10:1 ratio of balls to fly ash and milling chamber and balls were of tungsten carbide, the ball diameter was 10 mm. Toluene was used as the medium with an anionic surface active agent to avoid agglomerations; rotation speed of the planet carrier was 300 rev min −1.

A New Generation of Parabolic Trough Technology

Thermal Energy Storage Indirect moltensalt TES systems Allow solar dispatch ... Solana Solar Power Plant Overview Power Block TES Solar Field Solana 280 MWe Parabolic trough solar field 6 hours of thermal energy storage (TES) Innovative technology solutions for sustainability ABENGOA SOLAR Solana Generating Station . Solana . Has a 30year power purchase agreement (PPA) with Arizona .

Coal Handling Plants

Coal Handling Plant In Thermal Power Plant. The initial process in coal based thermal power plant is coal Function of coal Handling Plant in thermal power .. Read More. Ash Handling System In Thermal Power Plant. In thermal power plants, coal is used as a fuel for generating electricity. After burning of coal, 40 % of ..

Ball Mill For Thermal Power Plant

ball mill of thermal power plant · roller mill in thermal power plants. This is the first mathematical model of power plant Tubeball mills to cover the whole of mill and boiler complex, and analyzed its effects on the steam pressure ABB has reported their work in nonlinear coal mill modelling for vertical roller Get Pric Wear and corrosion preventative solutions ...

Mitsubishi Power | Small/Midsized Condensing Turbines

These turbines are recommended for plants where high reliability in power generation is required or in wasteheat recovery plants where power is generated from inexpensive fuels. While the main steam flows through the turbine and into the condenser, steam can also be bled from the turbine for feedwater heating to increase overall plant efficiency. Steam Turbine Specifiions. Type: Condensing ...

Lessons Learned from Existing Biomass Power Plants

Btu/kWh. A "typical" value is about 14,000 Btu/kWh (% thermal efficiency, HHV). Cogeneration The four cogeneration plants in the report—Okeelanta, Snohomish, Lahti, and Camas—are recent plants, using the latest technology, in traditional niches for biomass power: two at pulp and paper mills (Snohomish and Camas), one at a sugar mill (Okeelanta), and one at a municipal district ...

mill in thermal powerplant

mill in thermal powerplant. FOB Reference Price: Get Latest Price Description: Description of coal mills in thermal power plant coal mills in thermal power plant is also called raw meal vertical roller mill, and it is the core equipment applied for cement raw meal grinding. In 1971, first Φ1m ball mill in China was produced in Great Wall Machinery, and open the door to .

Ball Mill Working Principle And Main Parts

Ball Mill. SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefiion, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

Detailsof Thermal Power Plant Industries in Tamil Nadu S ...

Detailsof Thermal Power Plant Industries in Tamil Nadu Name of the Industry Name Address Category/Classific ation Consented Product Quantity with Unit 1 KUTTALAM GAS TURBINE POWER PROJECT Maruthur, Therizhandur PO Kuttalam TK Red Large Generation of electric power 100 MW 2 SURYADEV ALLOYS POWER PVT LTD(POWER PLANT) 298/2 New Gummidipoondi, .

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Latest Posts

- أسماء محجر الحجر الطبيعي يوتا

- تستخدم البائعين كسارة الحجر باركر

- استهلاك كهربائي بواسطة الدرفلة

- كسارة المعدات الإلكترونية

- معالجة الذهب بالخام الجزائر

- تعدين أسعار حديد التسليح

- PCZ بيرات المطرقة محطم

- بيع معدات معالجة الفحم المستعملة

- كسارة الفحم والشاشة المصنعة في اليمن

- تقرير افتتاح كسارة الفك

- صغيرة كسارة الحجر المستخدمة تجهيز منة في المملكة العربية السعودية

- فلاي الرماد المتطاير دعم ماكينات المصانع في مصر

- شركة سحق المصانع الألمانية

- للبيع تستخدم كسارة الحجر لمحجر

- الكرة مطحنة عملية مراقبة

- Personal Gold Wash Plant For Sale

- Ball Mill Germaney Lab

- Ball Milling Machine South Africa

- Skullcandy Crushers Mobile Crusher

- Major Factots Governing Plant Location

- Balmil Grinding 36

- Piece Detacher Moulin Law

- Density Of Stone Aggregates Mm

- Second Hand Stone Crusherin Delhi Ncr

- Mini Rock Crushers For Hobby

- Bauxite Industry In Central Africa

- Producer Track For Crusher In Europe

- Labo Grinder Mill Korea

- Secondary Crusher China For Sale

- For A Variety Of Minerals Jaw Crusher Price Stone Jaw Crusher