Clinker Grinding Plant Clinker Grinding Plant Suppliers And

Difference between Clinker and Cement

Clinker is produced inside the kiln during the cement manufacturing process. Raw mix is heated and then rapidly cooled to produce the marblesized pellets of clinker. Read: Clinker Manufacturing Process. Cement is produced by grinding clinker (added with different active ingredients to achieve the desired properties of cement) into a fine powder. 4

PNR 8717

M/S. Maharashtra Cement Plant (A Unit Of Shree Cement Limited Is Proposing Clinker Grinding Unit Near Villages: Patas And Kangaon, Taluka: Daund, District: Pune (Maharashtra). Company Is In Plan To Installation Of Clinker Grinding Unit Of MTPA In Two Phase And Of .

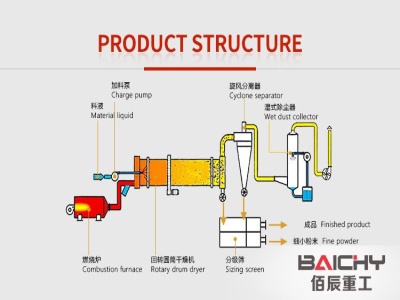

CCG Plant | Loesche

The CCG is a smallscale grinding plant designed to produce different types of cement. At its heart – LOESCHE's wellproven, stateofthe art LM CS vertical roller mill. From the feed hoppers, clinker or slag is conveyed to the mill, with the finished product being separated in a highefficiency classifier and collected in the baghouse system filter. Loadout options include either a ...

CHAENGMining Equipment Suppliers

CHAENGMining Equipment Suppliers. Production Line. Products. Slag Grinding Plant. Slag powder is highperforming admixture for concrete in that it increases the concrete's ability to resist compression, tension, shear, and bending stresses. A major trend that characterizes the building material industry is to replace equal amount of cement ...

China Ball Mill Machinery Cement Clinker Grinding Plant ...

Certifiion: Ce,ISO9001,SGS,BV Name: Ball Mill Machinery Cement Clinker Grinding Plant Keywords: Cement Clinker Grinding Plant Installation: Engineer Guide Warranty: One Year Except Wearing Parts Power: 11380kw

Avoiding Clinker Formation in Thermal Power Plant Boilers ...

· Clinker grinders are provided in boilers to grind large pieces of clinkers into small ones so that choking of the exhaust hole may be avoided, but it is observed in many thermal power plants that clinker grinders are out of service due to negligence or being considered a redundant feature. Due to this negligence large pieces of clinkers can choke the exhaust hole of the hopper and accumulation ...

Megatech International Private Limited, Alwar

Clinker Grinding Units. Rotary Kiln Plants. About Company. Nature of Business Exporter; Year of Establishment 2003; Legal Status of Firm Limited Company (Ltd./) Annual Turnover Rs. 50 100 Crore; Import Export Code (IEC) 13060***** GST No. 08AAECM6457C1ZH; We are among the highly prominent Manufacturers, Exporters and Wholesalers of premiumquality Cement Manufacturing Plants.

GGBS Production Line

· Appliion : Cement Plant Clinker Grinding Unit, Steel Mill Annual Output : 200,0001,000,000 tons Power Consumption : 3545 kWh/t Blaine Fineness : cm²/g . As a new type of high performance concrete admixture, ground granulated blast furnace slag (GGBFS) has all kinds of performance advantages about improving concrete compressive resistance, tensile resistance, .

Clinker grinding with limestone

· Suppliers Directory; Plant Loions; Data. Global Cement Report 14th Edition Database; Regions; Countries; Data Export ; Home » Forum » Technical Cement Forum » Clinker grinding with limestone. 28 posts. Time Posted 12/08/2014 14:35:11. shastrib says. Clinker grinding with limestone. Good Morning all, My experience with grinding clinker with limestone to produce OPC resulted in the .

Manufacturing Process – Continental Cement

Plants grind the raw materials with heavy, wheeltype rollers that crush the materials into powder against a rotating table. After grinding, the material is known as raw meal and is now ready for the preheater tower. Preheater Tower . Step 3 : Preheater Tower. The preheater tower supports a series of vertical cyclone chambers through which the raw meal passes on its way to the kiln. To save ...

Products

8094 % Cement Clinker. 620 % Fly ash. 05 % Gypsum. Export India. "Seven Rings PPC" is produced exclusively for export to India under the license of Bureau of Standard India (BSI). Specifiions: Composition: IS 1489 ( Part 1) :1991 Min 80% Cement, Clinker. Packed in 50Kg net PP/Paper Bag 15% Fly ash. 5 % Gypsum.

Cement mill

Clinker rapidly burned at the minimum temperature for combination, then rapidly cooled, contains small, defective crystals that grind easily. These crystals are usually also optimal for reactivity. On the other hand, long burning at excess temperature, and slow cooling, lead to large, wellformed crystals that are hard to grind and unreactive. The effect of such a clinker can be to double ...

Megatech International Private Limited, Alwar

Clinker Grinding Units. Rotary Kiln Plants. About Company. Nature of Business Exporter; Year of Establishment 2003; Legal Status of Firm Limited Company (Ltd./) Annual Turnover Rs. 50 100 Crore; Import Export Code (IEC) 13060***** GST No. 08AAECM6457C1ZH; We are among the highly prominent Manufacturers, Exporters and Wholesalers of premiumquality Cement Manufacturing .

CalPortland Invests for energy efficiency

quality clinker for grinding process 17 The plant uses approximately 100 Million kWh annually at an average cost of .08 per kWh. Heat Balance Existing Cooler 18 Multiple heat balance analysis were performed to determine appropriate design and calculate savings. Previous Clinker Cooler • The Cooler air supply uses 7 constant speed fans with damper controls for controlling mass flow of the ...

agro mills for clinker grinding

Cement clinker grinding plantChina cement grinding . The cement clinker grinding plant or the cement grinding station acts as an individual production line in the last period of the cement production process. In the finished product period, the cement clinker is ground by adding moderate mixing materials. Get Price And Support Online . Get Price; grinding in cement mill polycom roller press ...

Grinding mill supplier, grinding mill manufacturer ...

Clirik machinery is a professional grinding mill manufacturer,grinding mill supplier,devoted to provide grinding mill,ultrafine mill, raymond mill supplier, grinding mill manufacturer, grinding mill for sale,Raymond Mill

ENVIRONMENT IMPACT ASSESSMENT FOR SECIL LOBITO'S .

New Clinker and Cement Plant – Secil Lobito Volume 1_Non Technical Summary Rua Bento Banha Cardoso, 38 – Luanda Mail: tecproeng ∗ Tel.: 00244 222 394139/391870 ∗ Fax: 00244 222 331587 I1. 2. PROJECT'S OBJECTIVES AND JUSTIFICATION The present study refers to Secil Lobito's new Clinker and Cement Plant, which will be installed in a 40 hectares property loed in .

Cement Plant Wear Parts

More cement plant replacement wear parts, more alloy selection, more industry expertise. From pit to raw grinding, to preheater, kiln, and finish grinding, Columbia manufactures a full range of replacement parts for cement production. For example, we make large carbon steel mounting frames for roller mills; heat resistant steel preheater and ...

Project Cases / Cement Projects_ZK Ball Mill_Rotary Kiln ...

Guateala cement grinding plant. We have built a cement clinker grinding station with capacity of 1200 tons per day in Guatemala. The project adopts closed circuit process flow chart to produce ASTM C1175 GU and HE cement. The process main grinding equipment is clinker ball... View detailed. New Type Dry Method Cement Production Line. Capacity: 2,500tpd Supply Scope: Complete equipment for ...

Latest Posts

- عرض أحدث معدات التعدين r ppt

- جعلت منزل محطم حجر مصر

- آلة حجر سكريد للبيع السعودية

- مصنع كسارة الفحم السعودية

- التعدين السمور يشتري التحرير

- المصنعين صخرة محطم في مصر

- شراء غسالة الرمل

- كسارة الصخور الصغيرة الفك للبيع

- مزود كسارة الدولميت المحمولة في أنجولا

- شرائح مطحنة الكرة جزء لكل تريليون

- تكرير الذهب تكرير السودان

- معدات كسارة الفك

- لغرض تكسير خام الذهب

- طاحونة bmh ك

- مطحنة الفحم للبيع في الولايات المتحدة

- Small Power Vibrator Feeder Minerals Feeder For Mining Plant

- Used Conveyor Belting For Sale Texas Binq Mining

- Crusher Kuat Buatan Jepang

- Ultra Grinder In Iceland

- Grinding Phosphate Data

- Stone Crushing Plant With Capacity To 25tph

- German Made Mobile Sand Making Machines

- Heavy Duty Grinding Machine Poland

- Mining Companies In South Africa Impact

- Stone Crushing Machine From China Stone Crusher Machine

- Blooming Mill Price In Kenya

- Mining Minerales And Megatrends

- Fiji Clinker Cement Grinding Plant Manufacturers Crusher

- Mining Equipment For Sale In Mission Viejo

- Crusher Buckets Class