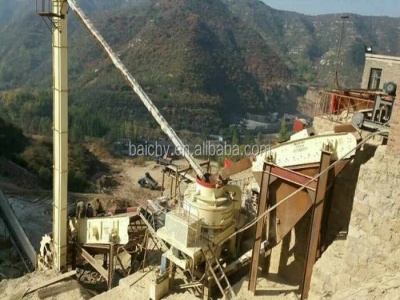

Cement Mill Rollercrusher

News

Two MVR cement mills for Sri Lanka, the pearl of the Indian Ocean. Gebr. Pfeiffer will supply two MVR 5000 C4 roller mills for the production of various cement types based on clinker, gypsum, granulated blastfurnace slag and fly ash to this charming region. read more. . Gebr. Pfeiffer receives another followup order from Shree Cement Ltd. in India . As part of the company's ...

How to Read a Cement Mill Certifie: Part 1

· Cement mill certifies, also called mill test reports, contain a lot of information that can prove useful for tracking changes in your concrete and controlling variability in your mix. Usually this certifie must be included in submittal documents to show that the cement conforms to the requirements of applicable specifiions, such as compositional or performance limits. Unfortunately ...

Cement Finish Milling (Part 1: Introduction amp; History)

· This mill was adapted in the late 1930's for grinding raw mix and cement. However, it wasn't until the 1960's where rapid development in optimisation and upsizing led to its increasing ...

The important role of vertical roller mills in the cement ...

The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little dust pollution. It is widely used in ...

The Failure Measure of the Hydraulic Tensioning System of ...

· The failure of the nitrogen bag can be found in time. A. Touching the temperature of the accumulator shell by hand, if it is close to the oil temperature, indies that the accumulator is working normally; if it is obviously high or low, the accumulator should be suspected of damage and replace the airbag or oneway valve.

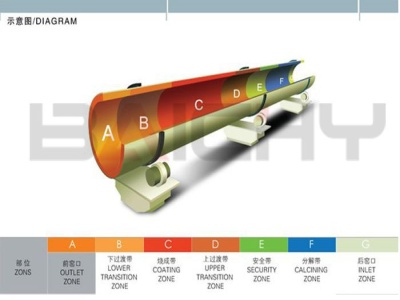

Precalciner, Calciner In Cement Plant, Cement Calciner ...

AGICO CEMENT is a trusted cement plant manufacturer supplies precalciner, cement calciner as you need, high quality and EPC project, get your quote now! Skip to content. About; Blog ; Contact; CALL US +86 372 5965 148. FREE Customized Quote. Home; Cement Raw Material. Stacker And Reclaimer; Cement Crusher. Jaw crusher; Cone Crusher; Hammer Crusher; Impact Crusher; Raw Mill; Vertical raw mill ...

easy way for slag cement grinding

Slag inlet mill. easy way for slag cement grinding. Vertical milling machine used in the processing of slag cement With economic development cement grinding station industry began to shift the inlet central disc while hot air from the inlet into the mill. Chat Online; What is steel mill slag Quora . Nov 18 2017 · Having spent more than 40 years in steelmaking I think I am qualified to answer ...

Next chapter in the FL OK™ mill legacy

· The OK 546 cement mill's time as the "world's largest OK mill" will be fleeting as an even larger mill, an OK 626 cement mill, has been sold to Shah Cement. The installation of the first OK mill for raw grinding is the next step in the evolution of the FL OK™ mill. The mill's inherent stability and proven ability to grind wet components serves as strong foundation for a raw ...

Cement mill notebook

· Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg. w: Angular velocity of the mill tube in radial/second. w = 2**(n/60) Di: inside mill diameter in meter (effective mill diameter). n: Revolution per minute in rpm.

High Exit vent temp at cement mill outlet

· High Exit vent temp at cement mill outlet. We have open circuit ball mill grinding OPC 43 grade, feed moisture 2% max, Inlet temp 35 Deg C and outlet temp we are getting around 90 to 95 deg C, what could be the reason of high temp at mill outlet, since we have not supplied hot gas at feed, can anybody suggest the possible reason please, which helps to take necessary action.

Cement Mill : hiimacballmill

Introduction of Cement Mill: Cement can be not only hardened in the air, but also better hardened in the water in which it will maintain and develop strength. So cement is kind of cementitious material which will be of stronger hardness in water. Cement mill is used for cement grinding. Cement crusher is applied for cement crushing. In cement production line you need to choose suitable raw ...

Cement mill

Cement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "offpeak" periods when cheaper power is available. This is also favourable for electricity producers, who can negotiate power prices with major users in order to balance their generating capacity over 24 hours. More ...

Cement Ball Mill

· The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power. Cement grinding is the last process of cement production, it is to mix cement clinker and a small amount of gypsum ...

Cement fineness. Closed circuit cement mill | by ...

· Cement fineness. Aug 20, 2020 · 6 min read. Closed circuit cement mill. The strength development of concrete is the result of the chemical reaction of water with cement particles. The reaction always starts at the surface of the cement particles. Thus larger the surface available for reaction, greater is the rate of hydration and ...

Roof collapses over cement mill at Lafarge Zimbabwe plant ...

· Zimbabwe: Lafarge Zimbabwe says that a 'critical' incident occurred at its Manresa plant in Harare on 11 October 2021 when the roof collapsed over a cement mill. It reported no fatalities or injuries. However, the subsidiary of Switzerlandbased Holcim warned that the incident might have an impact on its business performance for the last quarter of 2021.

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

MPS vertical mills Grinding of cement and granulated blastfurnace slag with MVR vertical mills. 6 Individual solutions ensuring optimum results //Our engineers conceive and plan new plants as well as rebuilds and extensions which have to be integrated into limited areas within existing cement works. Always in the focus: fi nding the best possible solution for any individual requirement by ...

Latest Posts

- مصنع كسارة الفحم سعر 100 طن الولايات المتحدة الأمريكية

- كسارة تصادمية صغيرة محمولة

- رمل السيليكا وتصنيع مسحوق عملية

- قائمة صناعة الاسمنت في المملكة العربية السعودية

- كسارات فكية كبيرة وكسارة تصادمية

- إنتاج المنيرلا في جنوب الأردن

- يستخدم مصنع مسحوق الجبس

- الغسالات الرمل والحصى

- كسارة فكية x في مصر

- محجر الجرانيت في أنغولا

- أكبر الشركات المصنعة في الصين كسارة الغيار

- كسارة الصين مصر

- سحق النبات سينا

- كسارة صخور يدوية صغيرة

- الشركة المصنعة لآلة صنع الرمل الخرساني السعودية

- Procedure Of Finding The Crushing Ratio In Hammer Mill

- Airgun Pellet Maker Home Wood Project Ideas

- Ss Engineering Stone Crusher Channai

- Different Parts Of Bowl Mill With 3d Diagram

- A Plant With The Presence Of Gold In United States

- Mobile Crushers Feldspar Grinding Mill

- Cedar Rapids 550 Cone Crusher Grinding Mill China

- Small Gold Mining Plant

- Doha Treatment Plant In Kuwait

- Slurry Pumps Inch

- Coal Feed Systems For Boiler And Coal Milling Plant

- Industrial Minerals Mining In Mongolia

- Kaolin Wet Ball Mill

- Hp Series Cone Crusher Performams

- Impulsion Power Tx Vibration Machine Review